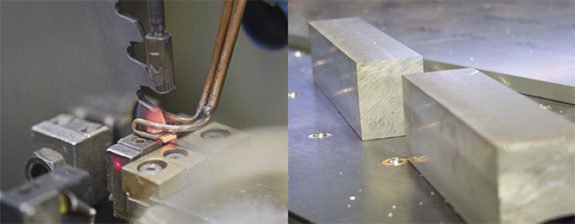

Above: A reconditioned blade is sharpened on the same equipment by the same operators that made the blade from scratch, says Specialty Saw's Keith Cotter. “If the blade sent in for service cannot be brought back to our standards, it is removed from the system.”

Saw blade teeth that, even when resharpened, cut like new

October 2019 - Assembling the pieces to an aircraft requires astute attention to every detail. From the years of engineering expertise leading up to a final design, to sourcing quality materials, and entrusting those part designs to fabricators who manufacture and qualify the parts that are then fastened together, all while adhering to stringent deadlines, every expectation must be met.

thyssenkrupp Aerospace NA, which also operates as TMX Aerospace, is entrusted with the critical components that keep aircraft safe, secure and in the air.

“We mostly cut aluminum rectangles and blocks, with a tolerance of 0.063 inches and gauges ranging from 0.125- to 8.5 inches,” says Rene Ornelas, operations manager at TMX’s Park City, Kansas, facility. “The blades we were using were wearing down quickly. We wanted to know how we could improve blade life as well as cutting quality and consistency.”

Within five days of using Specialty Saw's blades, TMX Aerospace experienced a 20 percent boost in cutting time on one saw.

The TMX team reached out to Specialty Saw Inc., Simsbury, Connecticut, and invited leaders to visit and offer suggestions. Specialty Saws President Dave Nagy visited the facility to see what TMX was working with before making any recommendations.

“I was impressed that this company we’d never worked with before came to see our facility before coming up with a plan for us,” Ornelas says. What struck Ornelas most was that he was promised that, after sharpening, any Specialty Saw blade would cut like new.

“I was looking forward to trying the new blades but even more to see if they held up to the promise,” Ornelas says. “We went from 72 teeth down to 48 teeth, [comparing] a California-style grind to Specialty Saw’s NFH grind. We run our saws 24 hours a day, seven days a week and within five days, we saw a 20 percent boost in cutting time on one saw.”

Good as new

TMX sent the blades back to Specialty to be sharpened. “After two weeks we put them back on our saws and we couldn’t believe it: they cut like new,” Ornelas says. “I was sold, it was incredible. Previous vendors couldn’t make that promise.”

Proven value

Specialty Saw holds reconditioned blades to the same tolerances as a newly manufactured blade. “A reconditioned blade is sharpened on the same equipment by the same operators that made the blade from scratch,” says Keith Cotter, director of sales and marketing at Specialty Saw. “If the blade sent in for service cannot be brought back to our standards, it is removed from the system. This remedies some of the most costly and frustrating situations our customers encounter.

“If a customer spends half an hour replacing a blade just to find that the sharpened blade from the local saw shop will not run, they have to start the process all over again,” he continues. “The ability to reduce downtime gives our customers an easy metric with which to prove our value.”

As promised, Specialty Saw's blades cut just as well after resharpening.

In addition to faster cutting times, Specialty Saw recommended blades with fewer teeth. “Specialty is actually further away from our facility compared to our former vendor, but that doesn’t matter because Specialty came up with a plan that ensures we always have blades,” Ornelas says. “We order every couple weeks and send out blades to be sharpened while replacing those blades with the newly sharpened ones we have. There are serial blade numbers and services recorded on each blade. So if they were sharpened or teeth replaced, a side grounded, etc., it is recorded.”

When employing blades with fewer teeth, costs decline. TMX ended up standardizing all its blades, swapping out the 72-count with 48-count teeth. Having fewer teeth on each blade didn’t hinder performance, it improved it. “These blades rip through the metal,” Ornelas says. “We also standardized the blade sizes we use from three down to two. It reduces blade orders and has had a huge impact for us.”

Newfound speed

Specialty Saw’s customer facility evaluations include an operational survey of all sawing equipment and procedures. “We cover blade sizes, tooth counts, tip geometry, speed and feed rates, clamping, lubrications and fluids, blade handling and storage, customer materials and cut tolerances, just to name a few,” Cotter says. “That intimate knowledge of customers’ equipment and relationships with the equipment manufacturers give us a unique ability to optimize the service center sawing operations all together.”

Changing blades less often contributed to a 40 percent reduction in downtime that was spent changing out blades. “Instead of two to three days of cutting time with blades that wouldn’t cut ‘like new’ after sharpening, we are now averaging five days of cutting or longer and they’re always sharp,” says David Delgado, plant manager at TMX’s Kansas location. “If you take into account that each blade change takes about 15 minutes, that adds up over time when you’re running the saws nonstop. We’re improving our output as a result.”

With blades cutting faster and for longer periods of time, TMX has had to adjust other parts of its production process, such as material handling and packaging, to keep up with increased output from the sawing department. “It’s a good problem to have,” Delgado says. “We had a guy who could keep up on his own but now he needs help, so we hired a floater to help keep things moving.”

Each blade has serial numbers and services recorded. If a blade is sharpened or teeth replaced, a side grounded, etc., it is recorded.

Specialty Saw’s blade variations are machine- and application-specific. Blades are designed with custom-built geometries for different grades of alloys, “even the hard stuff,” Cotter adds. “We have developed reliable blades for cutting beryllium copper, high nickel alloys, high silica alloys, including specific blade styles for bar, plate, shapes and extrusions.”

“Part of our education involves the differentiation between tolerance and finish,” adds Nagy. “If you can cut 30 to 50 percent faster while maintaining tolerance, why worry about the finish, unless finish is required by the downstream customer. If the material is just going to be machined anyway, why lose productivity chasing finish?”

As sawing technology changes, Specialty Saw finds the best strategy to keep up is to partner with industry leaders in equipment whether plate saws, billet saws, casting saws, cutoff saws, extrusion saws or fully automated robotic machining centers. “We work hand in hand with the manufacturer of the equipment because we believe that the blade is no better than the machine it is on and how well both are engineered to run together,” Cotter says.

TMX cuts aluminum without a mirror finish at its Park City location. “I was impressed with Specialty Saw’s [speed] suggestions about how I should run my saws in order to maximize blade life,” Ornelas says. “They were able to explain to me why a 48-tooth blade at a certain speed would produce the best kerf. We didn’t realize that with more teeth, it actually slowed us down.” MM